How to Adjust Trailer Hydraulic Brake?

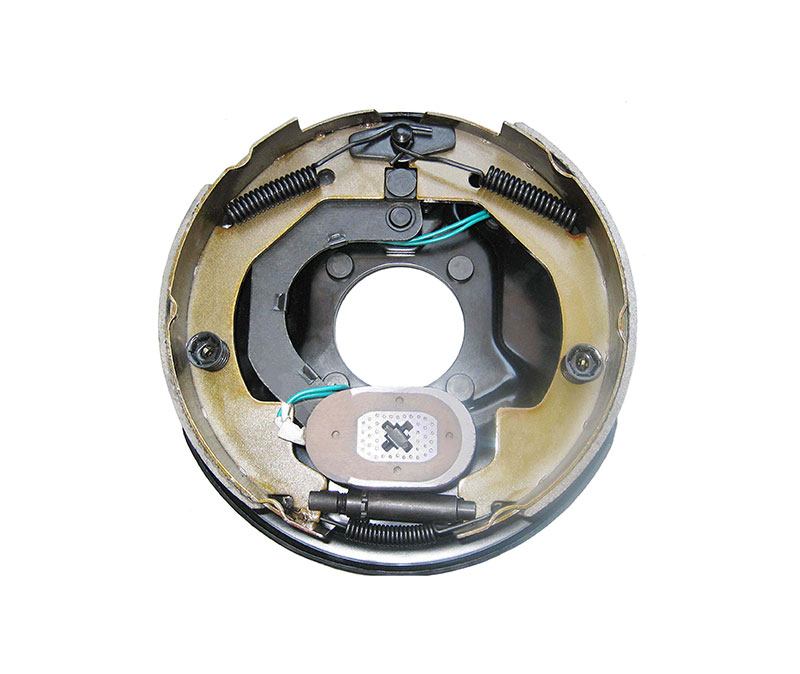

(1) In use, due to the wear of the brake shoe friction lining, the gap between the brake shoe and the brake hub is increased, resulting in a reduction in the braking torque, and thus the braking requirement cannot be met. If the brake lining friction lining is partially worn, not only the braking effect is poor, but also the Trailer Hydraulic Brake phenomenon occurs during the braking process.

The normal clearance between the brake shoe and the brake hub is about 0.3 mm. Generally, the clearance at the movable end of the brake shoe is slightly larger, and the clearance at the fixed end is slightly smaller (the upper clearance is 0.45 mm; the lower clearance is 0.3 mm). The specific value of the gap varies depending on the type and specifications of the brake. The upper gap is adjusted by changing the position of the rocker arm or turning the original position of the brake cam. The lower gap is adjusted by rotating the eccentric support shaft or the reverse buckle roller.

When checking the adjustment, first lift the trailer to make the trailer tire off the ground, and insert the gauge from the inspection hole between the brake shoe and the brake hub to measure the size of the gap. Then turn the brake hub and check the 3 different positions in the circumferential direction. Then tighten the lock nut and check again 1 time to confirm that it meets the requirements.

Trailer Hydraulic Brake

(2) Inspection adjustment of the left and right Trailer Disc Brake work conditions. The left and right brakes of the small four-wheel tractor are inconsistently adjusted. When the locomotive brakes at high speed, there will be dangers such as deviation and side slip. It is necessary to check and adjust carefully. When checking the operation of the left and right brakes of the trailer, choose a relatively flat and solid road surface.

First, test the brakes at medium speed and observe whether the braking effects of the drive wheels on both sides are the same. It can be determined according to whether the length of the two-wheel sliding drag marks on the ground is consistent. If they are inconsistent, you can relax the brake with good braking effect, make the two sides reach the same, and then perform high-speed emergency braking. In high-speed emergency braking and point braking, the braking effect of the wheels on both sides should be the same, and the braking distance (the length of the printing trace) should be less than 6 meters from the start of braking to the complete braking, otherwise the two should be adjusted in the same way. Side brakes. If the requirements are not met repeatedly as described above, the friction lining should be replaced in time until it meets the requirements.

As a Hydraulic Disc Brake Caliper Supplier, our company specializes in providing various types of trailer brakes. If you need it, please feel free to contact us and we will be happy to help you.

Previous RV Types