A solution to the noise of the brake device.

A solution to the noise of the brake device.

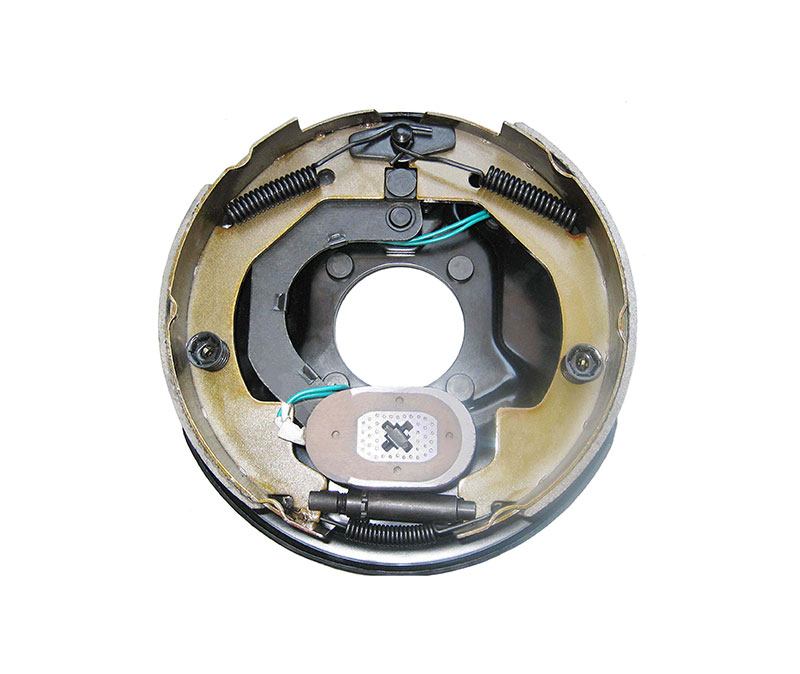

Trailer Drum Brakes utilizes a brake transmission mechanism to cause the brake shoes to press the brake linings against the inside of the brake drum, thereby generating braking force, decelerating the wheels as needed or stopping at the shortest distance to ensure safe driving, and ensure that the car is parked reliably and cannot be automatically slipped.

Pneumatic brake devices are commonly known as brakes. There are many types of brakes, such as disc brakes, hydraulic brakes, block brakes, etc. These are the more common types of brakes. Brakes are used in a wide range of applications. For example, in mechanical equipment, brakes may be used as long as they are mechanically moving.

Electric Drum Brake

Electric Drum Brake may make a "beep" sound during use, especially disc brakes. How do you do this? Don't worry, Xiaobian has found a way to check the noise of the brakes, which can help everyone solve this problem very well.

The material of the brake pad can be changed, and some softer ones are selected, the density is relatively small, which can effectively reduce the noise; and an anti-noise piece can be added between the caliper body piston and the brake lining to make the piston It forms a certain slope and also has a good effect of reducing noise.

If you are using a brake device, if you are experiencing noise, try using the small editor to see if it can effectively reduce the noise or prevent noise.

Brake performance

The role of the brakes is not only reflected in cars, elevators, cranes, etc., but also in the operation of various equipment, its role is:

1. The brake can act on its own when the elevator power is cut off, and the brake shoe holds the brake wheel to stop the elevator. The deceleration of the elevator during braking shall not be greater than the deceleration generated by the clamped stop car or the car stopping on the bumper.

2. When the elevator stops running, the brake should be able to ensure that the elevator is stationary at 125 to 150% of rated load and must not be opened before starting again.

3. When the overspeed occurs in the elevator running and reaches the speed limiter action speed, the brake acts first, and the brake wheel is braked to stop the elevator. If the elevator traction machine brake is released when the power is on, the elevator can be operated; when the elevator power supply or the control power supply is cut off, or the elevator runs over the limit, overspeed, and immediately fails, the elevator stops running or cannot Starting, it ensures that the brake can achieve reliable braking when the elevator is in power outage and various accidents occur; when the elevator is in normal operation, the brake should be fully released, and the brake shoe must not have any contact with the brake wheel. Our company is Electric Drum Brake Wholesaler, welcome to come to consult.