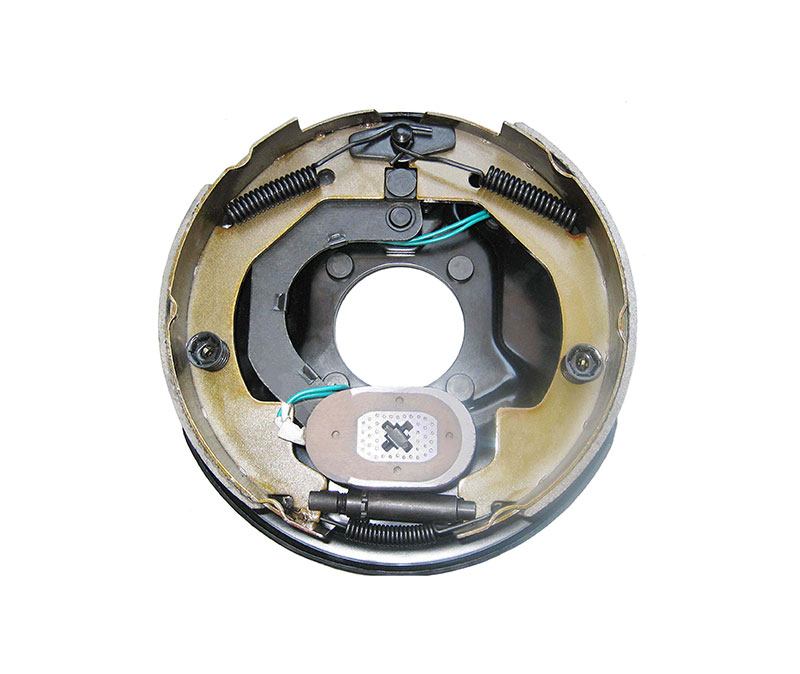

How does Trailer Brake Caliper effectively brake parking?

I believe many owners know that Trailer Brake Caliper is the brake we often say. In the event of an accident ahead, or when you want to stop,

you only need to apply the brakes to stop the car. Because of the key role of

the brake, the safety requirements of the brake are very high when the brake is produced, and more and more Trailer Galvanized Electric Brake

Suppliers are working hard on the safety of the brake.

When the excitation coil of the brake is connected to the rated voltage (DC), the electromagnetic force attracts the armature to disengage the armature from the brake disc. At this time, the drive shaft normally runs or starts with the brake disc. When the drive system is disconnected or broken When power is applied, the brake is also de-energized at the same time. At this time, the spring presses on the armature, forcing a friction torque between the brake disc, the armature and the flange to stop the transmission shaft quickly. In the brake heat dissipation environment is poor, the holding voltage is converted to 70% -80% of the rated voltage to reduce heat generation.

Trailer Brake Caliper

Friction is a process that must occur when the brake is running. During the friction of the brake lining and the coupling, the outer layer of raw materials will be lost and transferred due to mutual reaction, which will cause wear. This will slowly increase the gap between the brakes until the lining and drum can no longer be used, which is the working life of the brake.

From the perspective of the reliability of the brake, the friction index of the brake is very high, especially at high temperatures, it can still maintain a large friction index, that is, there is sufficient braking friction torque, but usually the more the friction index The greater the friction, the higher the resistance generated by the friction, and the greater the shear stress on the outside. Therefore, the loss or damage of the raw materials on the friction the surface will be more severe, the more abrasion will occur, and the working life will also be greater. The shorter, so friction and wear are two related and contradictory aspects during the friction period. Different working environments and conditions will have a different emphasis, but for brakes, some frictional resistance is required but it will not cause a relatively large amount of friction. The wear, brake wear and friction state during friction are related, and they vary with the working environment and the raw materials of the brake.

Everyone knows brakes. Because of its existence, emergency braking can make people in a safe state because of its existence. The brakes are divided into many types according to different scenes, and the material of each different brake is also different. Brakes are used in many industries and are loved by many manufacturers. Many brake manufacturers are producing brakes. Our company also has Trailer Drum Brakes on sale, welcome to consult.