Trailer Disc Brakes preventive measures

Vegetable oil-based brake fluid cannot meet the requirements of Trailer Disc Brakes, so high-boiling synthetic brake fluid is used. However, synthetic brake fluid has water absorption. Under certain conditions of use, the boiling point will decrease rapidly. To prevent the boiling point of the brake fluid from decreasing significantly, the following measures are usually taken:

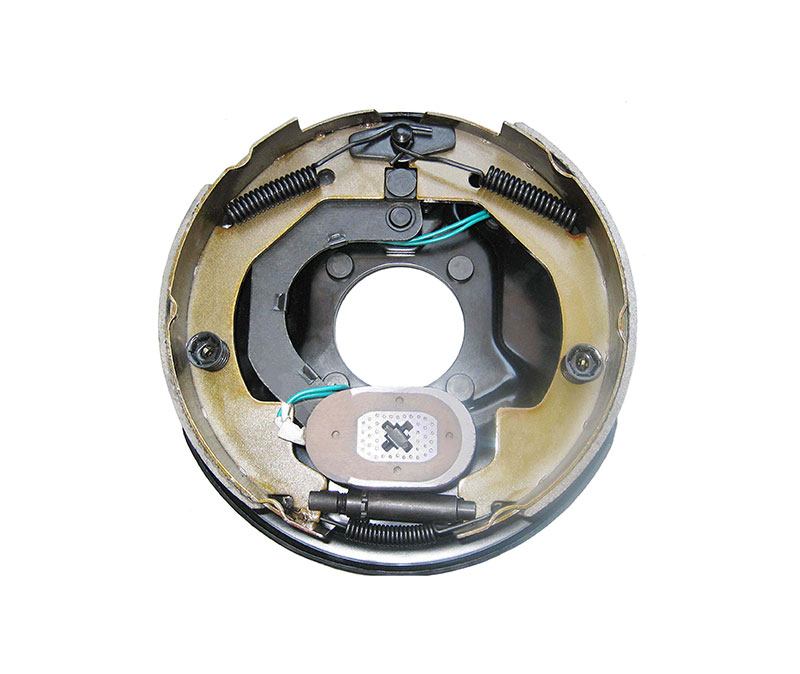

Trailer Disc Brakes

(1) Change the brake fluid regularly. In summer, 3 months or 5000 kilometers of smart tags are used; in winter, 6 months or 1000 kilometers, the brake fluid will be updated.

(2) Different types of brake fluid cannot be used interchangeably or mixed.

(3) Store the brake fluid tightly. In order to increase the temperature of the brake fluid, it is necessary to ensure that the piston can flexibly and automatically retract to prevent the brake from slipping or biting due to rust or card issuer. When the brake pads wear too much, the heat transferred to the brake fluid also increases rapidly. Therefore, worn brake pads should be replaced in a timely manner.

As a Trailer Stainless Steel Brake Caliper Manufacturer, I would like to share with you what problems the brakes are prone to.

The brake is one of the most important components in the car. Without the brake, we may not be able to complete the parking. However, many people who have driven the car will encounter a situation where the car runs to one side when braking. Let's analyze it from the perspective of the brake.

The reasons that may cause this situation are:

1. The gap between the wheel brake drum and the friction plate is different, and the touch areas of the two front wheel friction plates are too different.

2. The piston of the cylinder on one side of the wheel conflicts with the cylinder too much, there is air on the cylinder of the front wheel on one side, the hose is aging or the cylinder of the cylinder is bad, or the brake drum on one side of the wheel is out of round.

3. The degree of wear of the wheel brake shoe support pin migraine sleeve is different.

4. Frame deformation, front axle displacement, unsuitable front tow, loose steering organization, and elasticity of the two front steel plate springs.

After the problem occurs, the maintenance sequence: first test the brakes on the road; check whether the brake pipe of the wheel is leaking oil, whether the tire pressure is sufficient; the gap between the high-speed friction pads and the brake drum; check whether the pump has entered the air; remove For brake drums, check the brake components one by one for reasons; you should check the skills and steering organization of the frame or front axle.

Have you learned more about this situation now? Brake manufacturers remind you that if there is a problem with the car, you must perform maintenance in a timely manner, and do n’t be lucky.

Troubleshooting sequence for brake problems.

After the problem occurs, the maintenance sequence: first test the brakes on the road; check whether the brake pipe of the wheel is leaking oil, whether the tire pressure is sufficient; the gap between the high-speed friction pads and the brake drum; check whether the pump has entered the air; remove For brake drums, check the brake components one by one for reasons; you should check the skills and steering organization of the frame or front axle.

Our company also has China Electric Drum Brake on sale, welcome to consult.